Products >

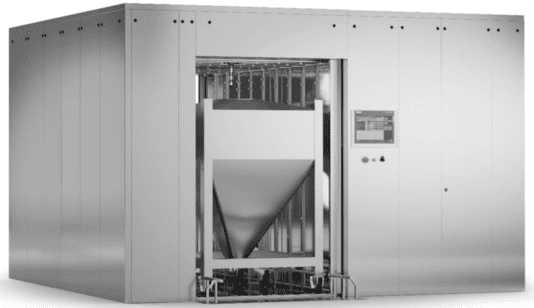

Pharma Grade Rack / Bin / Large Parts Washer

Pharma Grade Rack / Bin / Large Parts Washer

Réf : LC Series | Fabricant : SteelcoBelimed

Pharma Grade rack and bin washers are engineered and utilized for throughput, efficiency and validatable cleaning and drying of various materials and components used in the Biotechnology and Pharmaceutical Manufacturing processes.

Steelco has a deep understanding of the specific cleaning and drying requirements of the equipment and components used in pharmaceutical production.

LC PH range is a versatile system to wash containers, large components, ultracentrifuges, bulk chemicals: developed for all applications where it is necessary to treat large volume of items or large diameter / bulk components.

Key features

- From 4.250 litres / 150 cu.ft

- To 10.500 litres / 370 cu.ft

- Available in several chamber sizes, configurations and accessories to tailor each unit to exact requirements.

- Complete layout versatility (champer shape / left, right or shared technical area / hinged or sliding doors / floor or pit mounted)

- Steelco designs, develops, manufactures and tests all its own wash cart racks in-house, ensuring that the quality of this critical process is carefully monitored.

Specifications

- Washing chamber made entirely in AISI 316L stainless steel with rounded corner with edges and seams ground flush. All surfaces and welding points are polished and passivated.

- No dead-legs or crevices present in the chamber or sump. The chamber is self-draining and self-cleaning.

- Multiple oscillating sanitary washing arms made of AISI 316L stainless steel are located on the top and sides of the chamber to provide full washing and drying coverage for the load as well as the chamber.

- The heating elements enable variable drying temperature control. The HEPA filter is placed in line at the end of the drying path before entering the chamber and rack.

- Manual or automatic water sampling installed in technical area or in alcove on fascia.

- Conductivity sensor and TOC analyser for final rinse phase can be installed if required.

- User friendly control systems for SIEMENS / ALLEN - BRADLEY developed according to the latest ISPE GAMP© Guidelines and designed for FDA 21 CFR Part 11, EU Annex 11 compliance.

- 4 standard control architectures from stand alone to full virtualization.